A hydraulic pump is a self-contained unit that contains a motor, a water tank, and a hydraulic pump that produces hydraulic power to operate machinery and perform many heavy-duty tasks. They are often used in industrial, construction, automotive, and agricultural applications because of their ability to efficiently transmit large amounts of electricity in a compact design.

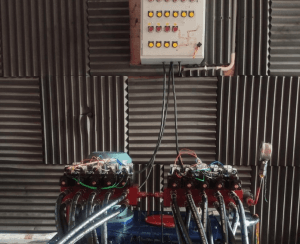

Motor: Powers the hydraulic pump. It can be electric, gasoline, or diesel powered. Hydraulic pump: Converts all energy into hydraulic energy (fluid flow). Reservoir/Tank: Holds hydraulic fluid (oil) and feeds it to the pump.

Pressure relief valve: Prevents excessive pressure by returning excess fluid to the tank.

Filter: Provides long life by cleaning the hydraulic oil. Accumulator.

Provides consistent energy by storing energy to be released when needed. The motor drives the pump, which creates hydraulic pressure by pushing fluid through the system.

Pressurized fluid flows through hydraulic lines to power actuators, such as pneumatic cylinders and motors. Actuators convert hydraulic energy back into mechanical energy to perform work such as lifting, pressing, or moving heavy objects. Standard hydraulic power unit: for many applications. Mini Hydraulic Power Unit: Compact and portable, ideal for small machines and mobile applications.

Micro Hydraulic Power Pack: Smaller and lighter for precision applications such as robotics. Customized hydraulic power packs: Tailored to specific machines and job needs. , injection molding machines and presses.

Deck machinery such as cranes. >- Versatile: Customizable for a variety of applications and needs.

– Regular fluid check: Ensure there is sufficient fluid and change or add as needed.

– Regular fluid check: Ensure there is sufficient fluid and change or add as needed.

>- Clean water filter: Change or clean filter to prevent bacteria from entering the body. The power plant is essential and provides efficient, cost-effective solutions for many industries.